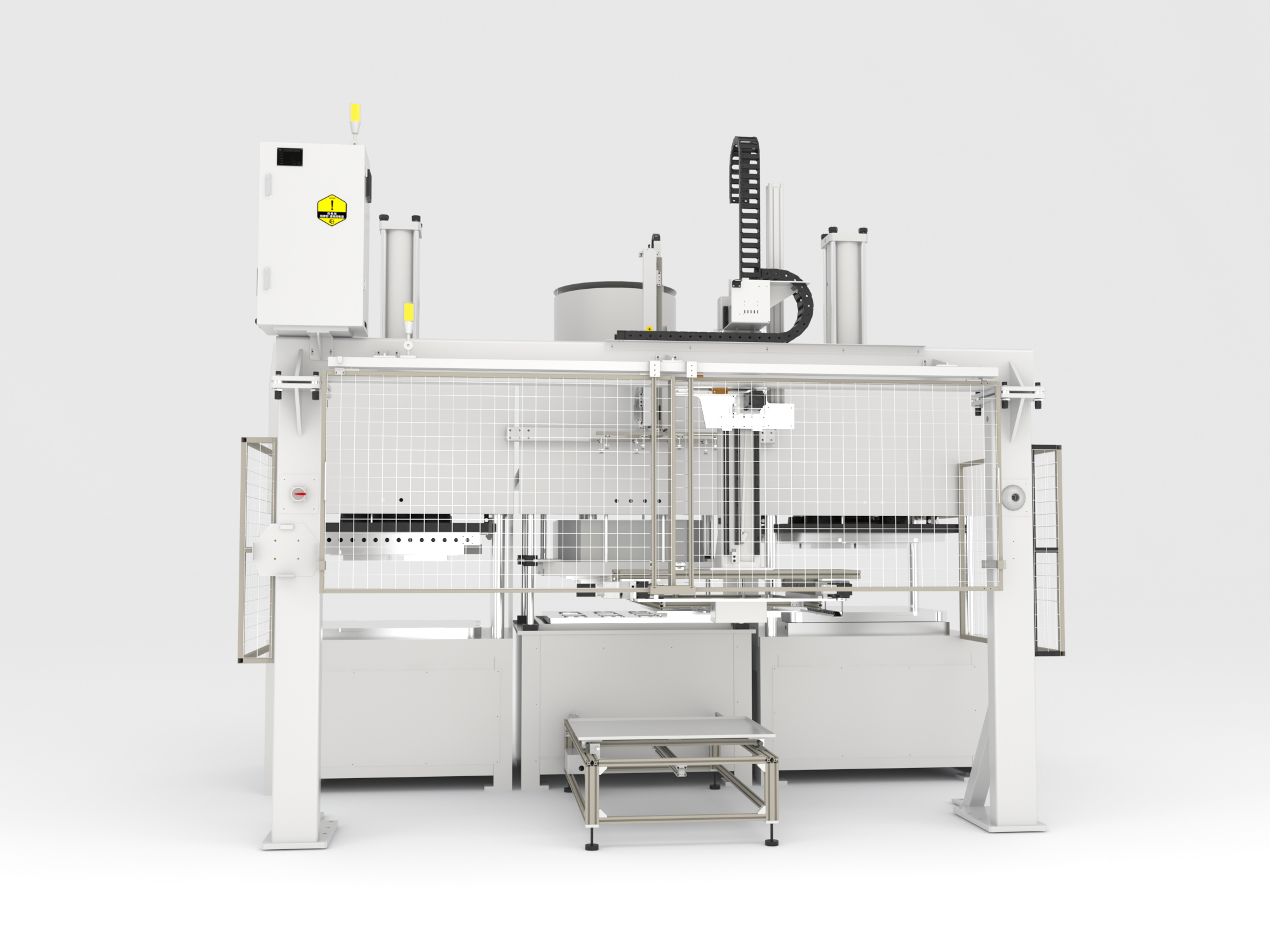

Paper mold forming machine manipulator

- Introduction

- Video

Paper molding machine manipulator, combined with paper molding machine, can automatically shape all kinds of paper film, mechanical hand through automatic take, place wet mold and dry mold products, to achieve unmanned production molding. Servo motors drive the transverse part, the draw out part of the finished arm, the draw out part of the telescopic arm and the down part of the finished arm, which can have different cross out and down positions. In the paper molding machine products and mold, the mechanical hand can automatically and accurately take out the product, can be placed more points, can be arranged in order, circulation of goods, will not cause product deformation, will not touch the surface. Quick removal, high efficiency, small vibration, high precision, long service life, reduce the defective rate of products, ensure the safety of operators, reduce labor, reduce waste.

(Equipment 3d layout)

1. Four-axis servo double-arm manipulator equipment is produced automatically from raw material supply to finished product output. One person can operate multiple sets of equipment, greatly reducing manpower expenditure.

2. The automatic continuous production function of the equipment can be realized, and the wet billet can be transferred to the hot pressing mold automatically after the paper mold equipment suction molding; Automatic hot pressing products after drying, products automatically transferred to the stack count.

3. The equipment is equipped with safety interlocking device.

4. The equipment can be switched between automatic mode, manual mode and single cylinder production mode to ensure the normal production of the manipulator equipment when the paper mold equipment is changed into molds or maintained. The manipulator is equipped with alternating stacking mode and normal production mode switching.

5. Safety device interlock is installed in the door and window for access to four-axis servo double-arm manipulator equipment. (mechanical and electrical interlocks)

6. The operation cycle of the mechanical arm of the molding machine can be controlled by the control system from wet billet forming, wet billet transfer, hot pressing shaping, shaping product transfer, as a production cycle.

The mechanical arm of the paper molding machine is used to take and put the environmental protection tableware after it is formed. Combined with the paper molding machine, various paper molds can be automatically formed. The mechanical arm can automatically take and place the products of wet mold and dry mold to realize the unmanned production of molding.