DD small "thunder" fast manipulator

- Introduction

- Video

(Product display)

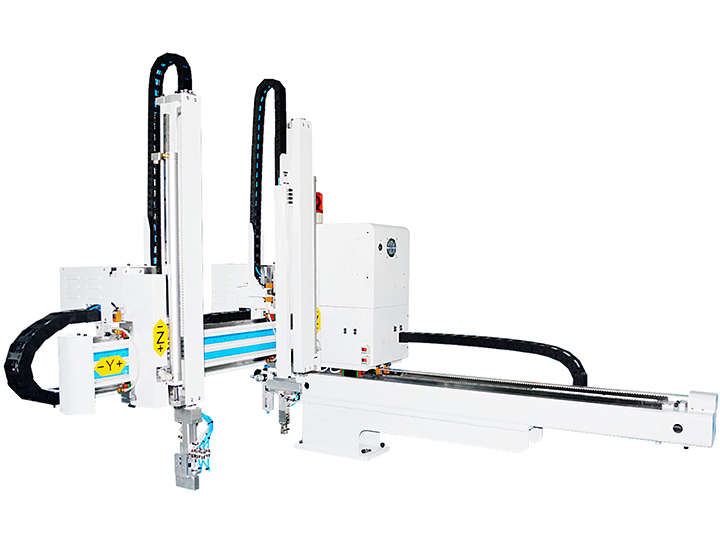

· crosswalk is a servo motor, the motor and controller are imported famous brands, with fast speed, accurate positioning and high reliability, the crosswalk positioning accuracy can reach 0.1mm, and the power is larger, to ensure the quality and thrust stability. The position of taking and placing can be set by oneself.

· precise ball screw drive is adopted for transverse motion, with less noise, smooth movement and faster transverse speed.

· the body structure is rigid, and the upper and lower parts are driven by cylinders. High precision linear slide rail is adopted for horizontal and upper and lower shafts, which can bear high load and high speed operation and have long service life.

· double-section arm adopts rigid aluminum alloy structure beam and imported high-precision linear slide rail, specially designed belt double speed mechanism, up and down cylinder stroke is halved, which improves the speed and stability of up and down, the machine is low in height, suitable for the plant with low height.

· the protection position of the safety door can be set on the electrical control panel to protect the electric hand and the injection molding machine.

· operating system: handheld operator, friendly interface, exchange of Chinese and English, easy to learn, a variety of functions, procedures for selection, can be automatic, manual. 64 sets of mould memory, simple operation and design when changing mould. Automatic fault detection, display on the screen for easy adjustment.

· all electric controllers are independently developed, and according to the current situation of domestic injection molding machines and the actual situation of incomplete safety protection measures, more safety protection functions are added and supplemented in the electric hand controller to provide safety protection for operators, injection molding machines and electric hands to the maximum extent. The operation or process with special requirement can also be changed according to customer's need to adapt to customer's special mould.

· the electric controller has built-in quick operation function, which can be customized when the customer needs. Using this function can shorten the whole cycle time, and further improve the production efficiency of the single machine.

· the speed and position of entry and exit can be set on the operation panel, no need to climb on the manipulator beam for manual adjustment.

· the speed regulating valve is fully integrated in the side, and has Chinese annotation name and adjustment direction, which is convenient and intuitive to adjust and reduces the possibility of misoperation.

· the downward speed in the main arm mold and the product placement speed outside the mold are independently adjusted without affecting each other.

· with functions of clamping, holding, blowing, sucking and cutting. Can be connected to the reception table, conveyor belt, plate detection group, spray device, water cutting device.