Gear Box Automatic Assembly Production Line

- Introduction

- Video

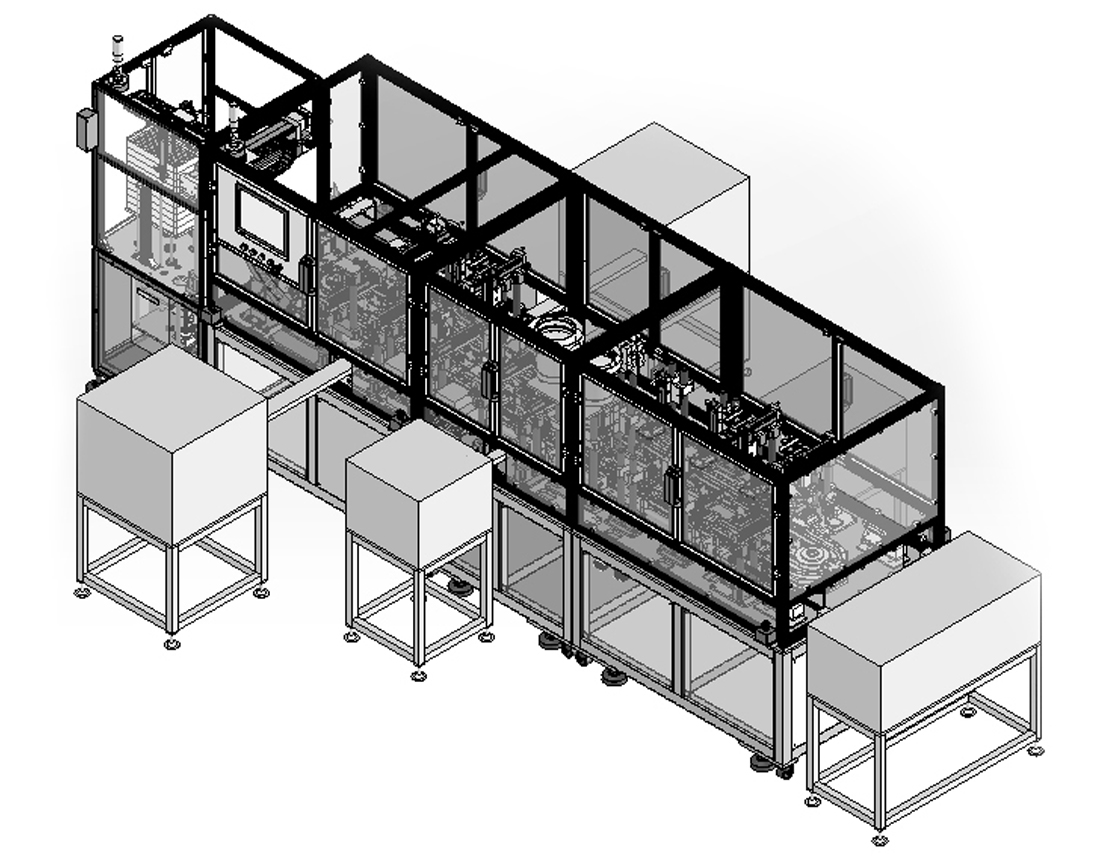

(Equipment renderings)

2. Reasonable structure arrangement, high operation efficiency, strong equipment stability and low failure rate.

3. Fully arrange the operating space of the equipment according to ergonomic principles.

4. Modular design is adopted to facilitate debugging and installation.

5. The maintenance cost is low, and the wearing parts are basically bearings, belts, etc., which can be replaced quickly.

6. The equipment has completed a total of 17 processes, greatly saving labor costs and increasing output.

7. The device has door opening and stop function.

The automatic assembly line of wave box is mainly used in the assembly of motor gear reducer of household sweeping robot. It adopts annular guide rail, which is easy to operate and can save a lot of manual assembly, and provide production capacity and reduce cost for enterprises